There are variety of bricks that can be used for different types of construction. The vast majority are made up of clay and kiln-fired.

FACING BRICK

A quality, durable bricks with an attractive appearance for external used above ground.Cladding a building in a quality facing brick provides not only an attractive facade, but also ensures the long term future of the structure. It is even true to say that some facing bricks become more attractive with influence of time. Facing bricks are a safe and long lasting building material. Their unique absorption properties contribute to a healthy living climate, whilst their strength ensures that ongoing maintenance costs are negligible.

This bricks is used for the exposed masonry, which mean the bricks need not to be plastered, therefore this type of brick will produce a natural looks. Furthermore this is the most cheaper facing as the manufacturing process is highly automated.

BUILDING BRICK

also called common, hard, or kiln-run brick, is made from ordinary clay or shale and is fired in kilns. They are used for general purposes, where appearance is not important. These bricks have no special shoring, markings, surface texture, or color. Because building bricks are generally used as the backing courses in either solid or cavity brick walls, the harder and more durable types are preferred.

LOAD-BEARING BRICK

They can be either common or facing bricks. They specified average compressive strength limits depends on their classes.

ENGINEERING BRICK

Engineering brick can burnt at exceedingly HIGH temperatures. It possesses a dense and strong semi-vitreous body, conform to defined limits for strength and water absorption. This kind of brick usually used in civil engineering works that require high load bearing capacity, good chemical resisting characteristics and good in damp-proof.

STOCK BRICK

Stock Bricks are a traditional type of brick. They are slightly irregular shape. Manufacture of this brick by using mechanised moulding process. The clay is wetted to a so-called "soft mud" and then moulded to shape, before being allowed to dry prior to firing in the kiln. Much of the process is automated. For this type of brick, a wide range of colours is available. In price, as well as style, stock bricks fall between the wirecuts and the handmades. This type of brick is currently one of the most popular.

Stock Bricks are a traditional type of brick. They are slightly irregular shape. Manufacture of this brick by using mechanised moulding process. The clay is wetted to a so-called "soft mud" and then moulded to shape, before being allowed to dry prior to firing in the kiln. Much of the process is automated. For this type of brick, a wide range of colours is available. In price, as well as style, stock bricks fall between the wirecuts and the handmades. This type of brick is currently one of the most popular.

HANDMADE BRICK

Handmade Bricks are literally made by hand by skilled craftsmen throwing clay into moulds. Each brick is unique and they have a pleasing and distinctive appearance with a creased face (known as a smile) as well as longstanding durability and desirable. - Many most admired historic buildings were built with handmade bricks. They are very much the thing for prestige housing projects. This type of brick is the most expensive of the facings, but well worth it on prestige jobs.

Handmade Bricks are literally made by hand by skilled craftsmen throwing clay into moulds. Each brick is unique and they have a pleasing and distinctive appearance with a creased face (known as a smile) as well as longstanding durability and desirable. - Many most admired historic buildings were built with handmade bricks. They are very much the thing for prestige housing projects. This type of brick is the most expensive of the facings, but well worth it on prestige jobs.

|

| Handmade brick |

CLINKER BRICK

Clinker brick is overburned in the kiln. Clinker bricks are usually rough, hard, durable, and sometimes irregular in shape. Pressed brick is made by a dry-press process, rather than by kiln firing. Pressed bricks have regular, smooth faces, sharp edges, and perfectly squarecorners. Ordinarily, they are used like face brick.

GLAZED BRICK

This kind of brick has one surface coated with a whiteor colored ceramic glazing. The glazing forms when mineral ingredients fuse together in a glass like coating during burning. Glazed bricks are particularly suited to walls or partitions in hospitals, dairies, laboratories, and other structures requiring sanitary conditions andease of cleaning.

FIRE BRICK

Fire brick is made from a special type of clay. This clay is very pure and uniform and is able to withstand the high temperatures of fireplaces, boilers, and similar constructions. Fire bricks are generally larger than other structural bricks and are often hand-molded.

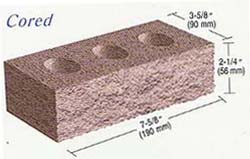

CORED BRICK

Cored brick have ten holes, two rows of five holes each-extending through their beds to reduce weight. Walls built from cored brick are not much different in strength than walls built from solid brick. Also, both have about the same resistance to moisture penetration. Whether cored or solid, use the more available brick that meets building requirements. European brick has strength and durability about equal to U.S. clay brick. This is particularly true of the English and Dutch types. Sand-lime brick is made from a lean mixture of slaked lime and fine sand. Sand-lime bricks are molded under mechanical pressure and are hardened under steam pressure. These bricks are used extensively in German.

The Demonstration of Making Bricks Machinery and Manually

Making brick machinery

Making brick manually

.png)

Not Bad... I like the handmade brick!

ReplyDeletel prefer the Stock bricks ~they are most useful~

ReplyDeleteWow there is a hand made brick ... like it ....

ReplyDelete